You are looking to outsource the development and manufacture of your cosmetic products ? For over 20 years, we’ve been helping brands to develop and manufacture their ranges of cosmetic products on a white-label or custom development basis. Thanks to the experience we’ve acquired working with some of the biggest international groups, we can offer you excellence, quality and Made In France in our support and production of your products.

As Europe’s leading manufacturer of sheet masks, an expert in powder cosmetics (masks, scrubs, wraps, peel-offs) and a major player in the manufacture of skincare products (creams, lotions, serums, scrubs, massage oils, etc.), we adapt to the trends and constraints of your markets by developing high-quality organic, natural, vegan and ethical cosmetics.

As a subcontractor and contract manufacturer of cosmetic products, here are a few tips and key steps to ensure the success of your tailor-made cosmetic project.

Understanding the manufacture of tailor-made cosmetics

Tailor-made cosmetics manufacturing involves creating products that are specifically adapted to the needs and preferences of each brand. This approach makes it possible to stand out in the market and meet consumers’ precise expectations.

There are various possibilities and solutions for developing a customised cosmetics project. The one we are presenting to you today is the one we offer our customers : full-service package. Development from scratch, from R&D through to dispatch of your products.

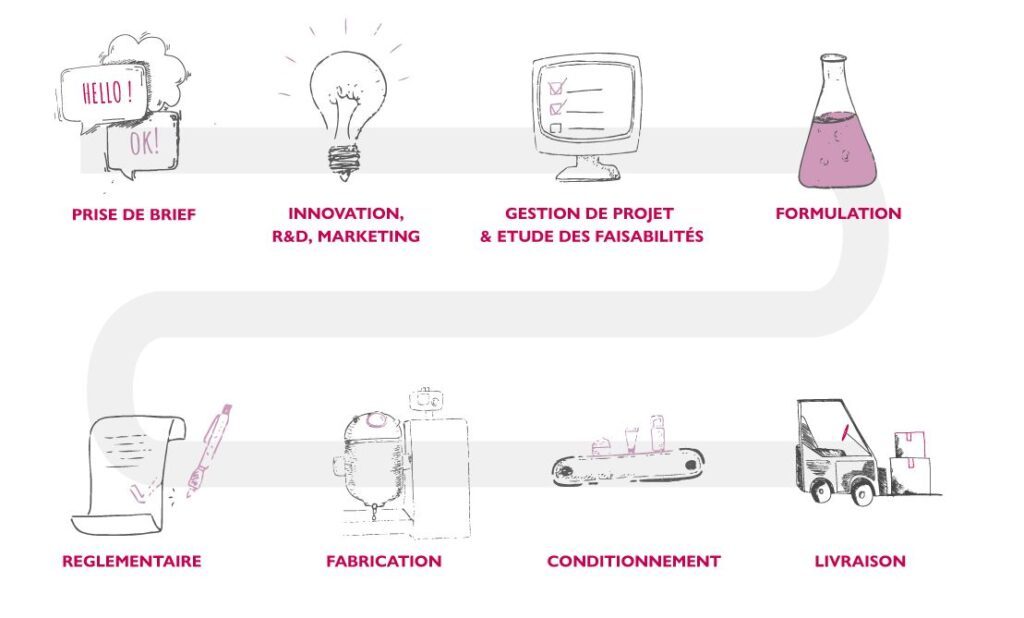

Stages in the development of your range of tailor-made cosmetic products

By offering you a full-service package, we make available to you all the expertise acquired from the world’s leading cosmetics companies, to ensure the success of your project.

From conception to market launch, we support you at all stages of the development of your cosmetic project.

Development of tailor-made formulas :

- Briefing : Our sales team will listen to your project, your needs and your objectives. We help you define your technical specifications by identifying your expectations, your budget, your schedule and your constraints.

- Innovation : Our innovation, R&D and marketing team study your specifications and analyse your precise expectations to determine the product concepts best suited to your project, as well as the cosmetic ingredients best suited to your brief.

- Project management : Our project team studies the technical feasibility of your brief and determines a theoretical formula as well as the costs involved (formulation, regulations, packaging, etc.). Its role is also to coordinate the various stages of your project (prototypes, set management, purchasing, regulations, industrial trials, production, quality, etc.).

- R&D Formulation : Our R&D team then develops the first laboratory-scale prototypes until we find your formula ! A tailor-made cosmetic product that reflects your image.

- Regulatory : Our regulatory team ensures that the bespoke cosmetic products developed for your brand comply with the regulations in force in the market where they will be marketed, throughout the cosmetic product development life cycle at Lessonia.

- Testing and validation : Once the formula has been validated, we carry out all the necessary tests to guarantee the safety and efficacy of your custom cosmetic products (challenge test, stability test, compatibility study).

Manufacture and packaging :

Manufacturing and quality control :

At Lessonia, we scrupulously respect good manufacturing practices. We have a modern factory adapted to the manufacture and packaging of cosmetic products. Our cleanrooms are specially adapted and dedicated to the manufacture of cosmetic products. In these areas, everything is measured and controlled : air quality, humidity, temperature and products. Quality samples are taken throughout the manufacturing and packaging process to ensure the safety and optimum quality of your cosmetic products.

Manufacture of bulk cosmetics :

Depending on the complexity of your cosmetics project, we recommend carrying out an industrial trial before launching large-scale production. This test, also known as a driver, enables the entire production process to be validated, and any associated problems to be identified and resolved. Once these stages have been validated, the bulk cosmetics can be manufactured.

It is in our clean room dedicated to the manufacture of cosmetic products that our operators combine and mix all the cosmetic ingredients, following a manufacturing sequence. We have a wide range of mixers for making creams, lotions, serums, oils, scrubs, powders, masks, etc., from 50 L to 2,000 L.

This equipment enables us to produce over 1,000 tonnes of bulk cosmetics a year.

Packaging your cosmetic products :

Once production is complete, we move on to packaging the products in our dedicated 8,000 m² factory. Thanks to our fully automated equipment, we can pack your products in jars, bottles, tubes and sachets, and handle all production volumes.

Your products are ready to ship ! Now it’s your turn.

The guarantee of 100% Made in France production

Our 16,000 m² industrial site is located in Saint-Thonan, Brittany, and comprises two plants. We guarantee 100% made in France and 100% Breton production because everything is made on our premises. You will be able to promote the message of Made in France and French cosmetics in your communications around your cosmetic products.

By outsourcing the manufacture of your private label or tailor-made cosmetics to us, you can be sure of working with a trusted partner whose responsiveness, quality and human values are rooted in the company’s DNA.